Planned GM Production Halt for Over a Month

General Motors will temporarily halt operations at its Flint Assembly plant in Michigan for a period of over a month during the Christmas and New Year holidays. This shutdown, however, is not related to a drop in product demand. Instead, the automaker is preparing to carry out large-scale work at the production site.

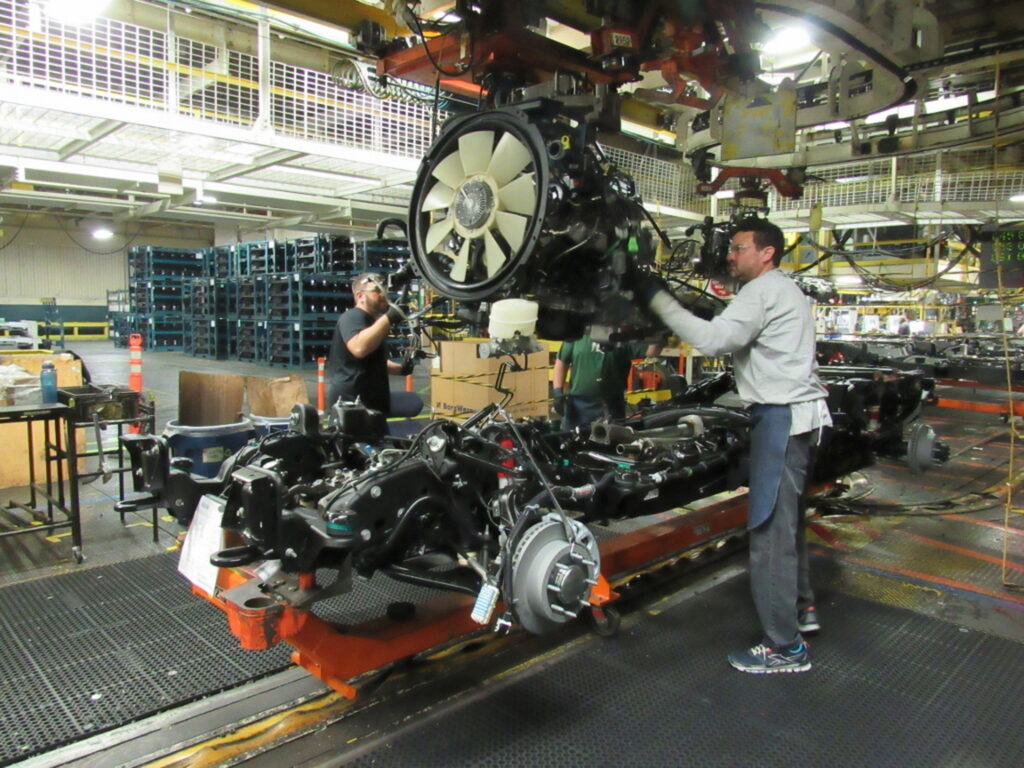

The Flint Assembly plant is currently responsible for the production of heavy-duty Chevrolet Silverado HD and GMC Sierra HD pickups. Production lines will be halted on December 24, and work will only resume on January 26, 2026.

For this plant, a longer break during the holiday season is a common practice, but it usually does not last this long.

Reasons for the Shutdown

In a statement provided to GM Authority, the company stated:

“Flint Assembly will undertake an extended holiday shutdown to complete planned maintenance and project work.”

While this sounds quite straightforward, GM did not provide details on what exactly these “project works” entail.

One possible reason could be preparation for the implementation of the new Gen 6 small block V8 engine, the launch of which is expected for the 2027 model year. This timeline may align with plans, although for now, this is just speculation.

Bowling Green Plant Shutdown

This is not the only GM plant closing for an extended period. The manufacturer also confirmed that the plant in Bowling Green, Kentucky, where the Chevrolet Corvette is produced, was halted this Monday and will not resume until January 12. Typically, this site closes for only two weeks at the end of the year, not four.

In this case, the break is likely needed to avoid excessive inventory stockpiles. Sales of sports cars like the Corvette typically slow down in winter, so there is no point in continuing their production when demand is low. Recent data indicates that across the United States, there are 46 vehicles of the 2024 model year, 1,417 of the 2025 model year, and 4,981 of the 2026 model year available in inventory.

Similar extended shutdowns at auto plants, especially for carrying out upgrades, are strategic steps to prepare for future products. Implementing new technologies, such as engines, often requires significant changes to production lines. For Bowling Green, the situation is somewhat different—here, the key factors are seasonal demand and inventory management logistics, which is typical for niche, high-cost products. Such decisions indicate an adaptation of production to market conditions and long-term model lineup planning.

by

by