Experts highlight three key points in the future of car manufacturing:

The Era of “Dark” Factories

Machines have helped people build cars faster and more accurately for decades, but this relationship is about to change radically. Some industry experts believe we are just five years away from a fully automated car factory without a single human.

Experts call factories operated solely by robots “dark.” Analysts from Gartner and Warburg Research predict that a Chinese automaker will likely be the first to completely eliminate humans from the production process, possibly as early as 2030.

However, other analysts believe the American auto industry will be only a step behind. According to Auto News, American automakers could also achieve fully automated production lines by 2030, although humans will still be involved in the plant’s overall operations. The changes will primarily affect the assembly process itself, not lead to the complete elimination of all roles.

Ambitions of Hyundai and Other Players

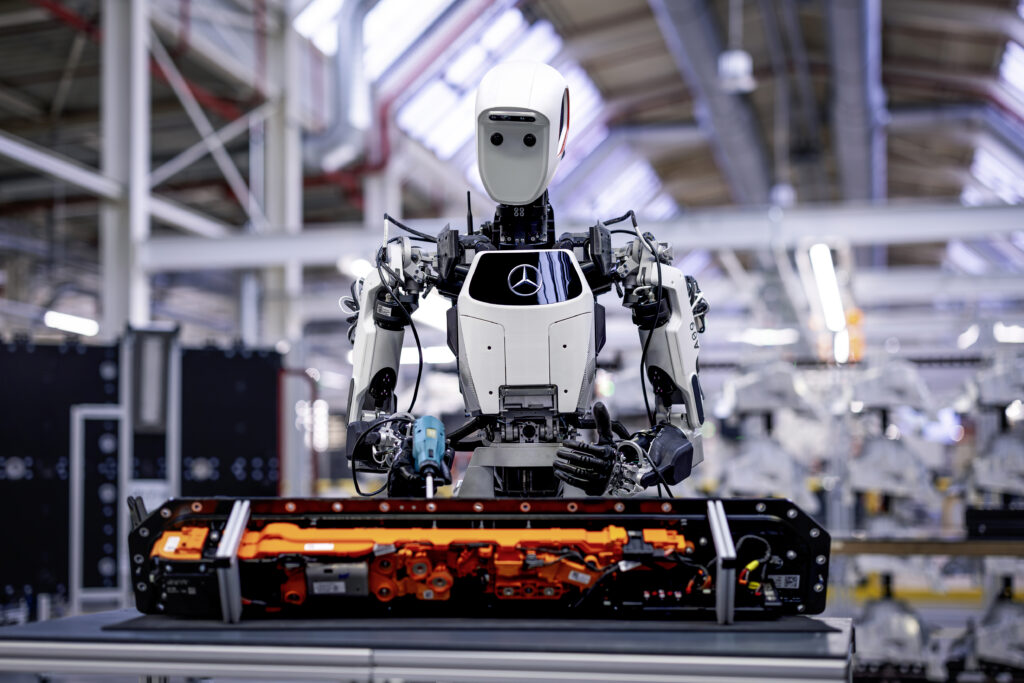

This is not science fiction. Hyundai already plans to deploy Boston Dynamics humanoid robots at its Georgia plant starting in 2028, while Mercedes is testing similar ideas on a smaller scale. Tesla is also building its own robots, and there is no doubt that every other major automaker seeking to cut costs is interested in this technology.

From a manufacturer’s perspective, the idea of a robotic workforce sounds fantastic. Robots don’t need to sleep, take vacations, or even breaks; they don’t require health insurance or pension contributions. Consulting firm Accenture claims that advanced automation can reduce costs and time-to-market by up to 50 percent.

Adapting Cars for a Robotic Future

This future technical shift is also changing car design principles. Parts may be added to the body in a different order to better suit robots, and complex components like wiring harnesses – one of the few elements currently not serviced by robots due to installation complexity – could be split up or integrated into body panels.

Social Implications and Resistance

That’s the positive side, while unions and aware workers easily see the potential negative consequences for entire communities when thousands of people are no longer needed. According to experts, people will still be needed for maintenance, logistics, quality control, software oversight, and system design, indicating that many jobs will be transformed, not lost. However, job losses will be inevitable, and there is no doubt that the UAW and other unions are unlikely to accept them silently. As automation intensifies, so will the tension between technological progress and workforce preservation.

The transition to highly automated manufacturing raises not only technological but also profound socio-economic questions. The success of this transformation will depend on the balance between corporate efficiency and social responsibility, as well as the readiness of governments and society to retrain a large number of workers. The pace of change may prove so high that traditional labor market adaptation mechanisms cannot keep up, requiring new, thoughtful approaches to employment and education policy today.

by

by