In the world of automobiles, some recalls go largely unnoticed, while others have far-reaching consequences. This year, a series of such high-profile cases are precisely related to engines. The key points of the situation:

The Scale of the Problem

In April, General Motors announced a recall of 721,000 6.2-liter V8 engines. Soon after, Toyota recalled over 102,000 V6 engines, and Honda recalled nearly 250,000 similar units. Stellantis is also dealing with issues concerning 112,589 turbocharged four-cylinder engines that have defects. Currently, over five million engines from five different automakers in the US are either recalled or under close scrutiny by federal agencies. This costly situation is affecting brand reputations.

The Root of the Problem

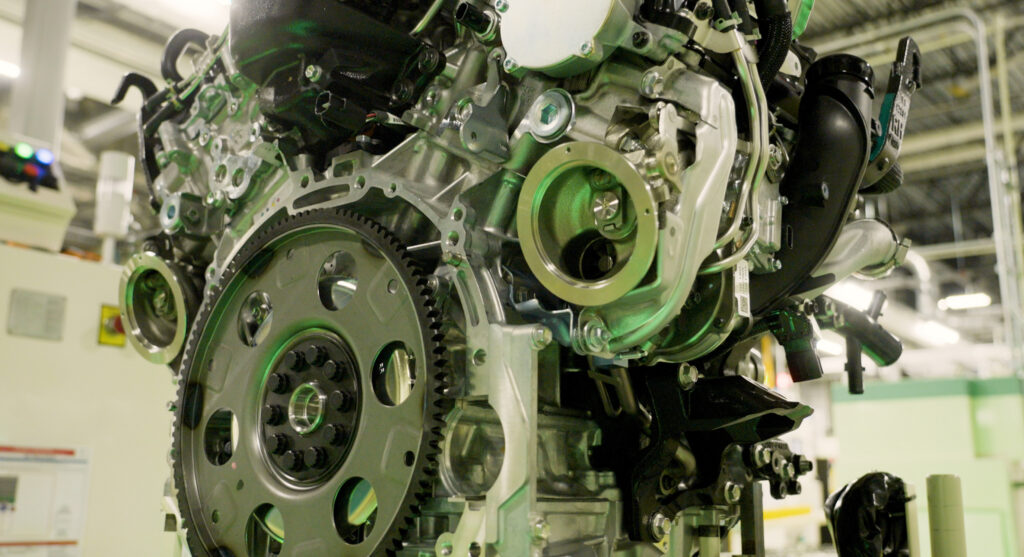

As reported by Automotive News, all these cases share a common root cause—the combination of lightweight oils and extremely tight tolerances in design. For decades, automakers have been downsizing engines to save fuel. To maximize these savings, they worked on improving thermal efficiency. Additionally, they needed to meet consumer demands for performance. Modern engines often combine various technologies for maximum power and efficiency.

The key to the operation of such engines is the use of lightweight, very thin motor oils, such as 0W-16 or 0W-20. These oils reduce resistance and friction, helping manufacturers achieve fuel economy goals. They are also critically important because they operate within the extremely small clearances of modern engine lubrication systems. It is these minimal tolerances that have become the main reason for the current recalls.

Previously, engines with larger clearances could compensate for microscopic machining errors during production. Today’s modern engines are not capable of this. If machining debris (metal shavings, dust) enters the engine crankcase or cylinder head, it can very quickly lead to catastrophic failure. A deeper analysis of the recalls mentioned above confirms this pattern.

How Manufacturing Debris Gets into Engines

The recall of GM’s famous LS V8 engine revealed problems related to bearing wear, crankshaft defects, and the presence of metal shavings in oil passages. Replacing one such engine takes about 18 hours. It’s no surprise that GM is spending over $1 billion to resolve the issue for its customers.

The court approved $57 million for the lawyers, while owners of the faulty GM V8 engines receive $3380 and a smile.

The Toyota V35A twin-turbo V6 engine installed in the Tundra pickup had a similar diagnosis. Tiny metal particles from machining got into the crankcase of some engines. The problem turned out to be so serious that last month Toyota added another 127,000 engines to the initial 102,000 already covered by the recall.

The Honda recall is related to engine bearings and connecting rods. Stellantis acknowledged that some of the engines being recalled may contain sand—another leftover component from the manufacturing process.

NHTSA Recall Statistics

According to data from the US National Highway Traffic Safety Administration (NHTSA) for the period from January 1 to December 14, 2025, the leaders in the number of recall campaigns (regardless of cause) were:

- Ford Motor Company — 143 campaigns

- Chrysler (FCA US, LLC) — 51 campaigns

- Forest River, Inc. — 36 campaigns

- General Motors, LLC — 26 campaigns

- International Motors, LLC — 24 campaigns

- Volkswagen Group of America, Inc. — 23 campaigns

According to Automotive News estimates, these and other similar failures will cost the involved brands over $8 billion in losses. A significant portion of this amount—about $5 billion—falls on Hyundai, which will spend funds related to the recall of 3.3 million engines. In these engines, claims have been made about the discovery of metal debris, faulty connecting rod bolts, and improperly installed piston rings.

Hyundai owners claim that the engines in their SUVs failed before reaching 80,000 miles.

Undoubtedly, modern engines are the pinnacle of engineering thought. When assembled properly, they provide greater power, higher efficiency, and better overall performance compared to older designs. The problem is that the proper manufacturing of such complex units is a serious challenge even for the world’s best automakers. The current mass recalls point to a systemic problem in the industry, where the race for efficiency and environmental friendliness sometimes outpaces the capabilities of flawless production. This is forcing a review of quality control at factories and may influence future engineering decisions, particularly regarding the transition to even thinner oils and even smaller technological tolerances. For millions of car owners, this translates into long waits for parts, inconvenience, and questions about the durability of the technology for which they paid significant sums.

by

by